As development of our 16 Blade advanced battery platform for the Nissan LEAF continues, one question the pops up somewhat frequently is: what are we planning to do with the old battery modules?

The short answer is that they find their way into stationary battery energy storage systems (BESS). While we’re staying focused on the primary automotive application rather than moving into the BESS space, we have been developing relationships and assisting other companies who are looking to establish themselves in this space. As 16 Blade production ramps up, we are going to need a few key customers that we can rely on to take the continuous supply of old modules that we’re pulling out of old low state-of-health battery packs. We would also like to see these modules quickly put to good use rather than sitting around doing nothing for long periods of time while waiting for a new home.

When we build a new 16 Blade pack we re-use several serviceable parts from the old pack including the entire battery pack enclosure. Therefore, any of our BESS customers need to repackage these modules in some way and we also need an efficient way of packaging these for transportation even if that is as simple as a wooden pallet or crate. In the process of exploring options, we think we have come up with a pretty cool solution that we would like to share with anyone who can make use of it.

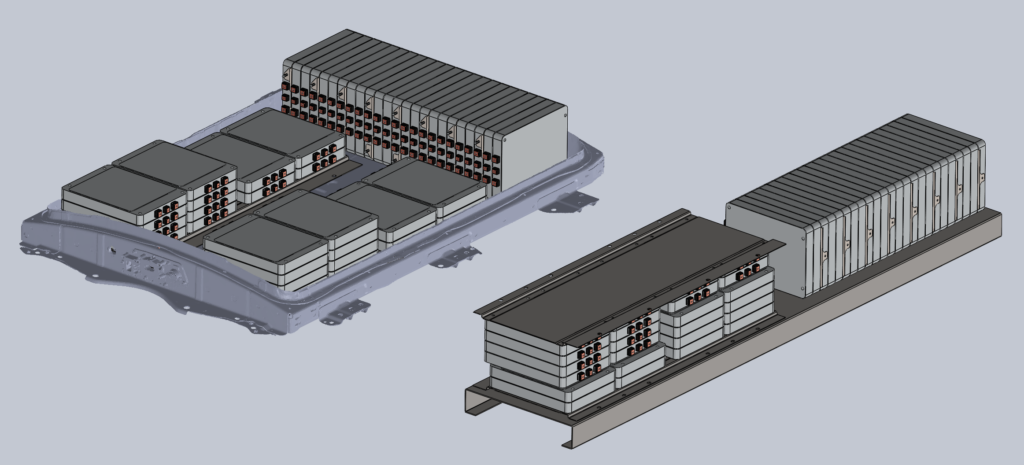

Noticing the common trend of needing one extra module to re-package 49 Leaf modules into a 14P14S stack suitable for use with 48V hybrid solar inverters, we initially explored how to do this as nicely as possible. That led to this prototype using mounting hardware designed in house:

While we were quite happy with the end result, it does require some time to build up one of these packs and that’s not something that we want to be doing at scale with us having more than enough production tasks to manage already.

The increased safety of this low-voltage configuration is great, but higher voltage systems are more efficient and the PV solar industry has mostly moved to higher voltage battery systems as a result.

With both of those factors in mind, we began exploring configurations that retain the original 2P96S configuration with minimal labour and parts required for reconfiguration. Keeping in mind requests that we’ve received from companies interested in larger industrial BESS applications, we also wanted any reconfiguration and packaging we did to add value and be useful in its next application. Remembering that these are packs are used and aren’t going to last forever in their 2nd life application, keeping them easy to access in the event that you need to repair/replace one was also considered to be of high importance in our thought process.

After kicking around some concepts for a while, we came up with the following design which we are releasing into the public domain with no rights reserved.

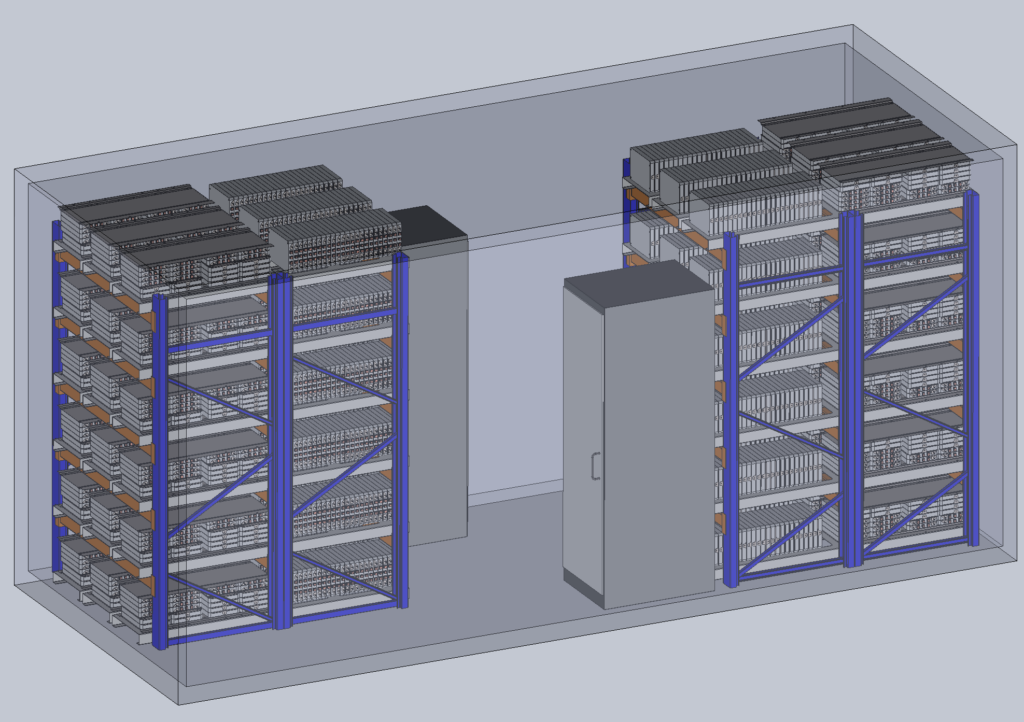

While this configuration may seem a bit long and strange at first, we think there there are some significant benefits when moving to larger industrial BESS applications that aren’t immediately obvious.

In applications with lots of these packs, being able to remove or install one complete pack at a time for service without needing to move lots of other packs has been a driving factor in this design. With long forks (or a common forklift with off-the-shelf slip-on extensions), this can easily be done in this case using conventional pallet racking. Furthermore, as side opening containers are really expensive for what they are, our design uses a far more cost effective 20ft high-cube tunnel container with doors at either end. Clearly this design could also be halved using a less-common 10ft container.

In this design, the inverters and other electrical equipment go in the middle (represented by the two cabinets) and a passageway at either end gives easy access and an alternative escape path in the event that one exit is blocked. Even starting with a smaller installation, the 20ft high-cube tunnel container with doors at each end makes sense to us over an overpriced 10ft container unless space on the site is at a premium. Clearly the 20ft would also leave space for future expansion.

Overall, we think this design has a lot of merits compared to just stuffing the original oddly shaped Leaf battery packs into shipping containers as we have seen done in the past. As previously mentioned, we are happy to freely share this design with anyone who can make use of it. Attribution is welcomed, but not required. However, wherever you are in the world, if you do build a BESS based on this design then we would love to see pictures so please get in touch. We’re also really looking forward to working with local BESS developers and operators to help put similar systems into interesting applications in our local New Zealand market.

Address:

14 Mowbray Street

Waltham – 8023

Christchurch

New Zealand